1. Essential Science and Nanoarchitectural Layout of Aerogel Coatings

1.1 The Origin and Meaning of Aerogel-Based Coatings

(Aerogel Coatings)

Aerogel layers represent a transformative class of functional products derived from the broader household of aerogels– ultra-porous, low-density solids renowned for their phenomenal thermal insulation, high area, and nanoscale architectural hierarchy.

Unlike typical monolithic aerogels, which are often fragile and challenging to incorporate into complicated geometries, aerogel layers are used as thin movies or surface area layers on substrates such as metals, polymers, fabrics, or building and construction products.

These finishings keep the core buildings of mass aerogels– especially their nanoscale porosity and low thermal conductivity– while offering improved mechanical resilience, versatility, and simplicity of application with techniques like splashing, dip-coating, or roll-to-roll handling.

The key constituent of the majority of aerogel coatings is silica (SiO ₂), although hybrid systems incorporating polymers, carbon, or ceramic precursors are significantly used to customize functionality.

The specifying feature of aerogel layers is their nanostructured network, commonly made up of interconnected nanoparticles developing pores with sizes listed below 100 nanometers– smaller than the mean free path of air particles.

This architectural constraint successfully reduces gaseous conduction and convective warm transfer, making aerogel coverings among one of the most reliable thermal insulators known.

1.2 Synthesis Paths and Drying Out Devices

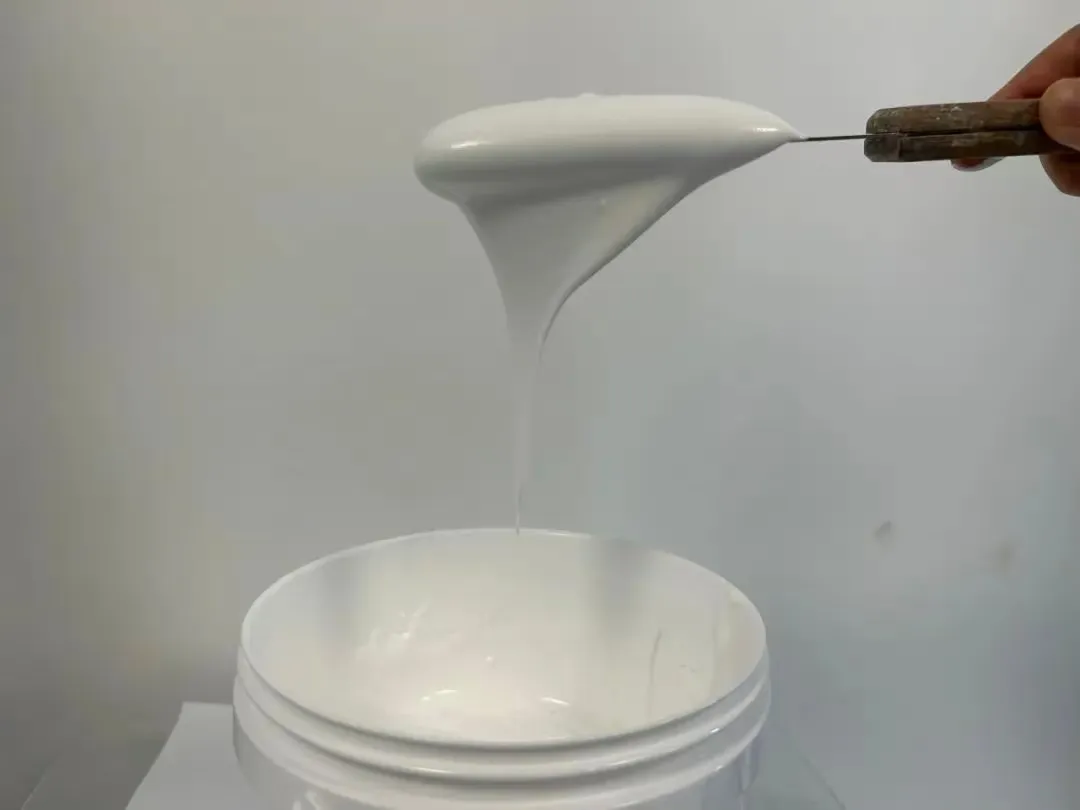

The construction of aerogel finishings begins with the development of a wet gel network with sol-gel chemistry, where molecular precursors such as tetraethyl orthosilicate (TEOS) undergo hydrolysis and condensation responses in a fluid tool to develop a three-dimensional silica network.

This procedure can be fine-tuned to control pore dimension, particle morphology, and cross-linking thickness by changing criteria such as pH, water-to-precursor ratio, and driver type.

As soon as the gel network is created within a slim film setup on a substrate, the critical obstacle lies in removing the pore fluid without collapsing the fragile nanostructure– an issue historically dealt with via supercritical drying out.

In supercritical drying out, the solvent (generally alcohol or carbon monoxide TWO) is heated and pressurized beyond its crucial point, removing the liquid-vapor interface and avoiding capillary stress-induced shrinking.

While effective, this method is energy-intensive and much less suitable for massive or in-situ finish applications.

( Aerogel Coatings)

To overcome these constraints, advancements in ambient stress drying (APD) have allowed the production of robust aerogel finishes without requiring high-pressure equipment.

This is accomplished via surface area adjustment of the silica network making use of silylating representatives (e.g., trimethylchlorosilane), which replace surface hydroxyl teams with hydrophobic moieties, reducing capillary pressures throughout dissipation.

The resulting finishings maintain porosities exceeding 90% and thickness as low as 0.1– 0.3 g/cm TWO, maintaining their insulative efficiency while making it possible for scalable manufacturing.

2. Thermal and Mechanical Efficiency Characteristics

2.1 Outstanding Thermal Insulation and Warmth Transfer Suppression

One of the most celebrated property of aerogel coatings is their ultra-low thermal conductivity, normally varying from 0.012 to 0.020 W/m · K at ambient problems– equivalent to still air and dramatically lower than conventional insulation materials like polyurethane (0.025– 0.030 W/m · K )or mineral wool (0.035– 0.040 W/m · K).

This efficiency originates from the triad of warm transfer reductions systems integral in the nanostructure: very little strong transmission as a result of the sporadic network of silica tendons, minimal aeriform transmission as a result of Knudsen diffusion in sub-100 nm pores, and lowered radiative transfer with doping or pigment addition.

In sensible applications, also slim layers (1– 5 mm) of aerogel finishing can accomplish thermal resistance (R-value) comparable to much thicker standard insulation, enabling space-constrained layouts in aerospace, developing envelopes, and mobile devices.

Additionally, aerogel coatings exhibit stable efficiency across a broad temperature range, from cryogenic problems (-200 ° C )to modest high temperatures (approximately 600 ° C for pure silica systems), making them suitable for extreme environments.

Their reduced emissivity and solar reflectance can be additionally boosted with the consolidation of infrared-reflective pigments or multilayer designs, improving radiative protecting in solar-exposed applications.

2.2 Mechanical Resilience and Substratum Compatibility

Despite their extreme porosity, contemporary aerogel coatings show unexpected mechanical effectiveness, specifically when reinforced with polymer binders or nanofibers.

Hybrid organic-inorganic formulations, such as those integrating silica aerogels with polymers, epoxies, or polysiloxanes, improve versatility, bond, and effect resistance, permitting the finishing to stand up to resonance, thermal cycling, and small abrasion.

These hybrid systems preserve good insulation performance while attaining prolongation at break worths up to 5– 10%, protecting against cracking under pressure.

Bond to diverse substrates– steel, light weight aluminum, concrete, glass, and flexible aluminum foils– is achieved with surface priming, chemical coupling representatives, or in-situ bonding during healing.

In addition, aerogel coverings can be engineered to be hydrophobic or superhydrophobic, repelling water and preventing dampness access that can degrade insulation performance or promote deterioration.

This combination of mechanical sturdiness and ecological resistance improves long life in outdoor, marine, and industrial setups.

3. Useful Convenience and Multifunctional Integration

3.1 Acoustic Damping and Sound Insulation Capabilities

Beyond thermal monitoring, aerogel coatings demonstrate significant capacity in acoustic insulation due to their open-pore nanostructure, which dissipates audio power through thick losses and inner friction.

The tortuous nanopore network restrains the proliferation of acoustic waves, specifically in the mid-to-high frequency array, making aerogel finishes effective in decreasing sound in aerospace cabins, vehicle panels, and structure walls.

When integrated with viscoelastic layers or micro-perforated facings, aerogel-based systems can attain broadband sound absorption with very little included weight– a critical advantage in weight-sensitive applications.

This multifunctionality enables the design of incorporated thermal-acoustic obstacles, lowering the requirement for several different layers in complicated settings up.

3.2 Fire Resistance and Smoke Suppression Characteristic

Aerogel finishes are naturally non-combustible, as silica-based systems do not add gas to a fire and can endure temperature levels well above the ignition factors of usual building and insulation products.

When put on combustible substrates such as wood, polymers, or textiles, aerogel finishes serve as a thermal obstacle, postponing warm transfer and pyrolysis, thus boosting fire resistance and raising retreat time.

Some formulas integrate intumescent ingredients or flame-retardant dopants (e.g., phosphorus or boron compounds) that broaden upon heating, developing a safety char layer that additionally protects the underlying material.

Furthermore, unlike lots of polymer-based insulations, aerogel coatings produce very little smoke and no poisonous volatiles when exposed to high warmth, enhancing security in encased atmospheres such as passages, ships, and skyscrapers.

4. Industrial and Arising Applications Throughout Sectors

4.1 Energy Efficiency in Structure and Industrial Equipment

Aerogel layers are changing easy thermal administration in architecture and facilities.

Applied to windows, walls, and roof coverings, they minimize home heating and cooling loads by reducing conductive and radiative heat exchange, adding to net-zero energy building layouts.

Transparent aerogel layers, specifically, enable daytime transmission while blocking thermal gain, making them ideal for skylights and drape walls.

In industrial piping and storage tanks, aerogel-coated insulation lowers energy loss in heavy steam, cryogenic, and procedure liquid systems, enhancing functional efficiency and minimizing carbon discharges.

Their thin profile enables retrofitting in space-limited locations where typical cladding can not be mounted.

4.2 Aerospace, Protection, and Wearable Technology Integration

In aerospace, aerogel layers safeguard delicate elements from severe temperature level variations throughout climatic re-entry or deep-space missions.

They are made use of in thermal protection systems (TPS), satellite housings, and astronaut suit linings, where weight savings straight translate to lowered launch prices.

In protection applications, aerogel-coated fabrics supply light-weight thermal insulation for employees and devices in arctic or desert atmospheres.

Wearable innovation take advantage of versatile aerogel compounds that keep body temperature level in clever garments, exterior equipment, and clinical thermal policy systems.

Moreover, research study is exploring aerogel coverings with ingrained sensors or phase-change materials (PCMs) for adaptive, responsive insulation that gets used to environmental conditions.

In conclusion, aerogel coatings exemplify the power of nanoscale engineering to fix macro-scale obstacles in power, safety and security, and sustainability.

By incorporating ultra-low thermal conductivity with mechanical flexibility and multifunctional capacities, they are redefining the limitations of surface design.

As production costs lower and application methods end up being more efficient, aerogel coatings are positioned to end up being a standard material in next-generation insulation, safety systems, and intelligent surfaces across sectors.

5. Supplie

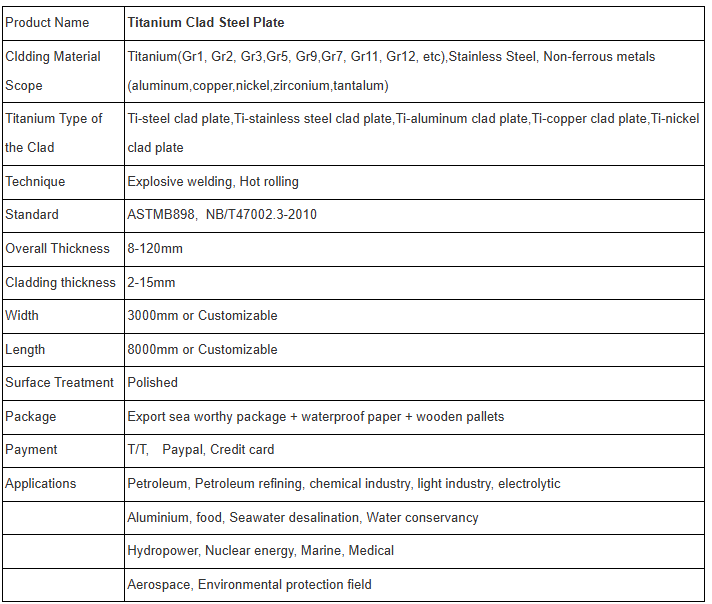

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

Tags:Aerogel Coatings, Silica Aerogel Thermal Insulation Coating, thermal insulation coating

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us