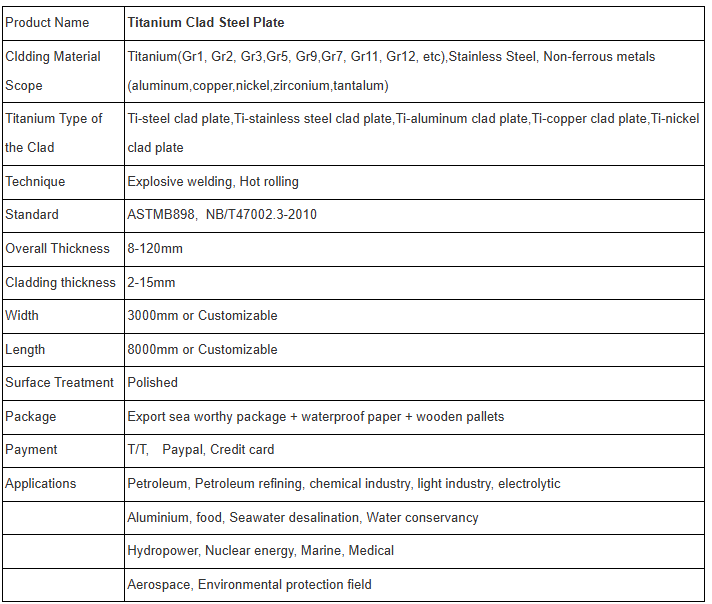

Intro: Revolutionizing Building Chemistry with Advanced Gelling Modern Technology

In the hectic world of construction and infrastructure development, time is critical. The Fast Solidifying Sulphoaluminate Gelling Agent has emerged as a game-changing additive in cementitious systems, allowing ultra-fast setting times, high very early strength, and exceptional longevity. Over the previous decade, CABR has become associated with this innovative product, transforming how concrete frameworks are built, repaired, and reinforced around the world.

(Rapid Hardening Sulphoaluminate Gelling Agent)

Firm Background: From Humble Starts to Market Leadership

CABR was founded in 2015 with a vision to redefine building and construction materials via chemistry and technology. Starting as a little R&D-focused business, the company rapidly recognized a growing requirement for rapid-setting additives that could sustain emergency repairs, tunneling tasks, and cold-weather concreting. Its development featured the development of an innovative Sulphoaluminate-based gelling representative, which supplied dramatically quicker hardening and better efficiency than traditional accelerators. Via continuous financial investment in research and manufacturing abilities, CABR broadened its reach across Asia, Europe, and Africa, coming to be a relied on name in specialized building and construction chemicals.

Flagship Product: Rapid Setting Sulphoaluminate Gelling Agent

The Quick Solidifying Sulphoaluminate Gelling Agent continues to be CABR’s most popular item. Created to enhance the hydration kinetics of cement, it makes it possible for concrete to set within minutes while creating remarkable mechanical stamina in simply hours. This makes it ideal for applications such as roadway patching, shotcrete, premade components, and winter season construction where delays are pricey. Designers and contractors commend its uniformity, compatibility with different concrete types, and capacity to execute under severe conditions– setting CABR apart in an open market.

Global Demand and Market Development

With urbanization speeding up worldwide and aging framework calling for immediate fixing, the need for fast-setting building materials has actually risen. According to recent industry records, the global market for rapid-hardening concrete ingredients is anticipated to go beyond USD 3 billion by 2030, driven by transport, power, and disaster healing projects. CABR’s Sulphoaluminate Gelling Representative has captured a considerable share of this broadening market, especially in countries spending heavily in highways, railways, and underground design.

Refine Optimization: Accuracy Design from Raw Products to Final Product

From the first day, CABR has actually concentrated on refining every stage of the production procedure to ensure top-tier performance. By thoroughly choosing high-purity basic materials and maximizing calcination temperature levels, the firm improved the reactivity and solubility of its sulphoaluminate substances. It additionally established proprietary mixing and grinding strategies that boosted diffusion and decreased clumping– key factors in accomplishing consistent efficiency on job websites. These advancements enabled CABR to deliver an extra stable, foreseeable, and effective gelling representative compared to common alternatives.

Quality Enhancement: Real-World Efficiency That Represents Itself

As opposed to concentrating on certifications alone, CABR focuses on real-world results. Area examinations and user comments have actually continually revealed that its Rapid Hardening Sulphoaluminate Gelling Representative exceeds standard accelerators in terms of very early toughness gain, workability, and lasting toughness. Professionals report much shorter healing times, fewer surface area problems, and improved resistance to freeze-thaw cycles– making CABR’s item a favored selection for time-sensitive and high-stakes building tasks.

Customization and Application Adaptability

( Rapid Hardening Sulphoaluminate Gelling Agent)

Understanding that no two building and construction situations coincide, CABR provides tailored solutions of its gelling representative to fit various concrete kinds, ambient conditions, and task requirements. Whether used in wet-mix shotcrete, self-leveling mortars, or grouting options, the product adapts perfectly to diverse applications. This flexibility has assisted CABR win contracts in massive infrastructure upgrades, extracting procedures, and armed forces engineering efforts worldwide.

Sustainability and Resource Effectiveness

As ecological issues expand, CABR has actually taken steps to align its manufacturing with lasting methods. The company has actually introduced energy-efficient kiln systems, decreased waste generation during synthesis, and discovered different raw resources to lessen environmental effect. Due To The Fact That its Sulphoaluminate Gelling Agent enables minimized concrete web content without endangering performance, it indirectly supports reduced carbon emissions– a crucial consideration in contemporary building and construction.

Looking Ahead: The Next Chapter of Growth and Technology

Entering its second decade, CABR remains to press the limits of what’s feasible in construction chemistry. Plans are underway to broaden into clever materials, hybrid accelerators, and electronic formulation devices that will better boost effectiveness and efficiency. With a solid foundation built on technical excellence and customer count on, CABR is positioned to lead the way in next-generation building solutions.

Final thought: Setting the Standard in Rapid-Hardening Modern Technology

Over the past ten years, CABR has actually established itself as a leader in the development and manufacturing of Fast Hardening Sulphoaluminate Gelling Representatives. With a front runner product that delivers unmatched rate, toughness, and flexibility, the business offers a growing international market with reliable, high-performance solutions. As building demands advance, CABR continues to be fully commited to technology, quality, and progress– shaping the future of building products one mix at a time.

Distributor

Concrete additives can improve the working performance of concrete, improve mechanical properties, adjust setting time, improve durability and save materials and costs.

Cabr-concrete is a supplier of foaming agents and other concrete additives, which is concrete and relative products with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality stained cement floors materials, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

Tags: calcium sulfoaluminate cement, calcium sulphoaluminate, calcium sulphoaluminate cement

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us