In the quest for products that can equal mankind’s technological leaps, one plain compound has actually become a silent game-changer: Spherical Light weight aluminum Nitride. Unlike its irregularly shaped equivalents, this carefully tuned variation of light weight aluminum nitride boasts a distinct round structure that opens amazing residential or commercial properties, making it important in whatever from microchips to spacecraft. This write-up explores just how Round Light weight aluminum Nitride is redefining efficiency throughout sectors, mixing scientific ingenuity with real-world influence.

1. The Scientific Research Behind Spherical Light Weight Aluminum Nitride

(Spherical Aluminum Nitride)

Spherical Light weight aluminum Nitride begins with the exceptional base material light weight aluminum nitride (AlN), a ceramic understood for three standout traits: extraordinary thermal conductivity, electric insulation, and chemical security. Think of attempting to cool down a smartphone chip with a product that both draws warm away successfully and rejects to carry out electrical power– that’s AlN’s superpower. Yet raw AlN often is available in jagged, irregular fragments, which behave like a stack of rocks: they leave gaps when packed together, compromising the final product. Spherical Light weight aluminum Nitride resolves this by transforming those rocks right into perfectly round grains, similar to marbles in a container. These balls load tightly, removing voids, and their smooth surface areas permit warmth to travel unobstructed. This architectural benefit improves thermal conductivity by approximately 30% contrasted to irregular AlN, while also boosting flow in production– think about it as turning a rough roadway right into a smooth highway for materials.

The magic of Spherical Light weight aluminum Nitride depends on its dual nature. It performs heat like a metal (about three times much better than light weight aluminum) but insulates power like plastic, making it perfect for electronic devices where overheating and short circuits are constant risks. Additionally, its light-weight composition (simply 3.26 grams per cubic centimeter) and resistance to rust make it a favorite in rough atmospheres, from engine parts to ocean-floor sensing units. This blend of residential or commercial properties, magnified by the round form, transforms an excellent material right into an excellent one.

2. Crafting Spherical Aluminum Nitride: From Laboratory to Production

Creating Round Light Weight Aluminum Nitride is a delicate dancing of chemistry and engineering, needing accuracy at every action. The procedure normally begins with high-purity aluminum and nitrogen sources, which respond under regulated conditions to develop raw AlN powder. However this powder is much from round– it looks like crushed glass. To reshape it, suppliers use methods that leverage physics and surface area tension, the same force that pulls water right into droplets. One typical technique is plasma spheroidization: raw AlN particles are fed into a plasma torch, where temperatures exceed 10,000 degrees Celsius. The intense heat thaws the bit surface areas, and surface stress pulls the liquified product right into excellent balls prior to cooling down. Consider it as utilizing a planetary blowtorch to brighten crushed rock right into beads.

An additional method is chemical vapor deposition (CVD), where gaseous precursors of aluminum and nitrogen are warmed in a chamber. As the gases respond, they transfer slim layers of AlN on little seed bits, slowly accumulating round grains. This technique permits precise control over dimension– from micrometers to millimeters– tailoring the powder for particular usages. Spray drying offers a lower-cost option: an AlN slurry is atomized into fine mist, which dries mid-air right into spherical droplets that solidify into consistent beads. Each method equilibriums price, scalability, and bit top quality, yet all share an objective: turning chaotic bits right into gotten rounds.

Quality control is essential. Manufacturers examine Round Aluminum Nitride for size consistency (making use of laser diffraction), pureness (via X-ray fluorescence), and thermal performance (with laser flash evaluation). A solitary set with askew bits could spoil a high-stakes application, so strenuous checks guarantee every bead satisfies exacting standards. This attention to detail is what makes Spherical Aluminum Nitride a reliable option for industries that can not manage failure.

3. Transforming Electronic Devices with Round Light Weight Aluminum Nitride

Electronic devices produce heat like a marathon runner sweats, and excess warm degrades efficiency or triggers failing. Round Light weight aluminum Nitride has become the best solution for maintaining devices cool down, many thanks to its unparalleled thermal conductivity and electrical insulation. In integrated circuit, for example, it’s mixed into thermal interface products (TIMs)– the gooey compounds that bridge chips and warmth sinks. Typical TIMs utilize silicone or metal fragments, but Spherical Light weight aluminum Nitride transfers warmth 50% faster, permitting CPUs to go for greater speeds without overheating. A leading semiconductor company just recently reported that making use of Round Aluminum Nitride in its gaming laptop computer chips decreased peak temperature levels by 15 levels Celsius, expanding battery life and component life expectancy.

Light-emitting diodes (LEDs) additionally benefit profoundly. LEDs convert most power right into light, but 20% becomes warm, which can discolor shades and shorten life-span. Round Aluminum Nitride is made use of in LED substrates, the base plates that draw warm away from the light-emitting diode. Its insulating residential or commercial properties protect against electrical leak, while its spherical form guarantees even heat distribution. This has actually allowed brighter, a lot more efficient LEDs for streetlights and mobile phone displays, cutting energy usage by approximately 30%.

Even flexible electronic devices, like wearable health displays, rely upon Round Aluminum Nitride. By installing the rounds in polymer films, designers develop flexible thermal pads that cool sensors without fracturing. This advancement is pressing the limits of what versatile tools can do, from foldable phones to medical patches that monitor glucose levels.

4. Round Aluminum Nitride in Advanced Ceramics

Ceramics are solid yet often weak, like a porcelain teacup that shatters if gone down. Round Light weight aluminum Nitride changes that story by toughening ceramics for demanding roles. When included in ceramic matrices, the balls function as microscopic reinforcements: if a crack starts to develop, the inflexible balls obstruct its course, taking in energy and protecting against devastating failing. This is why Spherical Aluminum Nitride-reinforced porcelains are made use of in cutting devices for machining hard metals– they stay sharp longer and resist wear.

In aerospace, these porcelains shine in engine components. Jet engines operate at temperatures going beyond 1,500 degrees Celsius, where steels soften. Ceramic composites with Round Aluminum Nitride retain strength at such extremes, decreasing engine weight by 20% compared to steel parts. This converts to fuel savings for airlines and longer maintenance intervals. A current development saw a rocket supplier using Spherical Aluminum Nitride-reinforced ceramic nozzles, which made it through 50% even more examination firings than previous styles.

Medical implants are one more frontier. Bioceramics made with Round Aluminum Nitride are being tested for bone replacements. Their rough spherical surface areas urge bone cell growth, while their chemical security prevents rejection. Early tests show these implants integrate with human bone quicker than conventional choices, supplying expect clients requiring joint fixings.

5. Powering Clean Energy Solutions

As the globe changes to renewable resource, Round Light weight aluminum Nitride is playing a quiet however important role in making systems extra efficient. Lithium-ion batteries, the heart of electrical vehicles and solar storage, create heat throughout billing and discharging. Too much warmth triggers destruction, reducing battery life. Designers currently install Spherical Aluminum Nitride bits in battery separators– the thin membrane layers that keep electrodes apart. The balls create a thermal pathway, spreading out warm evenly and avoiding hotspots. A pilot task with electric buses showed that batteries with Spherical Light weight aluminum Nitride maintained 90% ability after 1,000 charge cycles, contrasted to 70% for basic batteries.

Fuel cells, which transform hydrogen into power, additionally rely on Round Aluminum Nitride. In solid oxide gas cells (SOFCs), it functions as a permeable assistance framework for the electrolyte. Its high thermal conductivity helps keep the 800-degree Celsius operating temperature level, while its protecting residential or commercial properties keep electrical energy flowing in the best instructions. This has actually increased SOFC effectiveness by 15%, bringing tidy power better to taking on nonrenewable fuel sources.

( Spherical Aluminum Nitride)

Solar technology advantages as well. Round Light weight aluminum Nitride is layered onto solar panel reflectors, enhancing their capability to concentrate sunshine. The spheres’ high melting point (2,200 degrees Celsius) makes certain resilience under extreme sun, while their reflective surfaces jump even more light onto photovoltaic cells. This innovation could make focused solar power plants much more cost-effective, particularly in warm regions.

6. Aerospace and Beyond: Lightweight Stamina

Aerospace requires materials that are light yet solid, and Round Aluminum Nitride fits the bill flawlessly. Its reduced thickness (comparable to light weight aluminum but with greater toughness) makes it suitable for aircraft components. As an example, wing flaps made with Round Light weight aluminum Nitride-reinforced composites are 25% lighter than aluminum alloys, minimizing gas usage. Airlines estimate that a 1% weight reduction conserves millions of dollars in fuel each year, making this material an economic and environmental win.

Satellites encounter even harsher conditions: severe temperatures, radiation, and vacuum cleaner. Round Aluminum Nitride’s stability in these atmospheres makes it a top option for satellite architectural components. A current Mars vagabond mission utilized Spherical Light weight aluminum Nitride in its communication antenna housing, which maintained shape regardless of wild temperature swings (-140 to 20 levels Celsius). The product’s resistance to radiation also secures delicate electronics inside.

Looking in advance, Round Light weight aluminum Nitride can change space habitats. NASA is exploring its usage in 3D-printed lunar bases, where the balls would offer structural support and thermal regulation in the moon’s extreme day-night cycle. Such applications highlight just how a little spherical particle can aid human beings grab the stars.

Finally, Round Aluminum Nitride is even more than a specialty powder– it’s a cornerstone of modern-day technology. Its spherical structure amplifies the all-natural strengths of aluminum nitride, fixing challenges in electronics, power, and aerospace that once seemed impossible. From cooling down the chips that power our electronic lives to making it possible for cleaner power and more secure flights, this product is silently shaping a much more efficient, resistant world. As modern technology remains to evolve, Spherical Aluminum Nitride will remain at the forefront, confirming that sometimes, the smallest forms make the greatest impact.

7. Provider

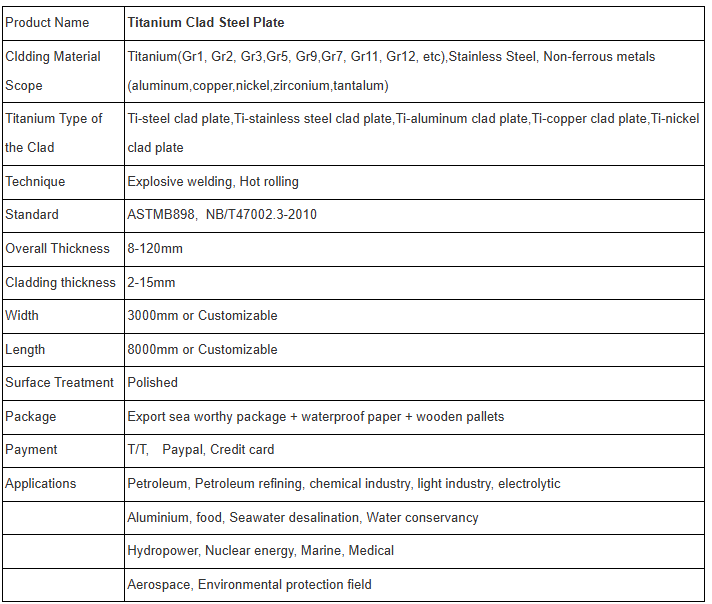

TRUNNANO is a globally recognized aluminum round tube manufacturer and supplier of compounds with more than 12 years of expertise in the highest quality nanomaterials and other chemicals. The company develops a variety of powder materials and chemicals. Provide OEM service. If you need high quality aluminum round tube, please feel free to contact us. You can click on the product to contact us.

Tags: spherical aluminum nitride, Aluminum Nitride, al nitride

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us